- Your cart is empty

- Continue Shopping

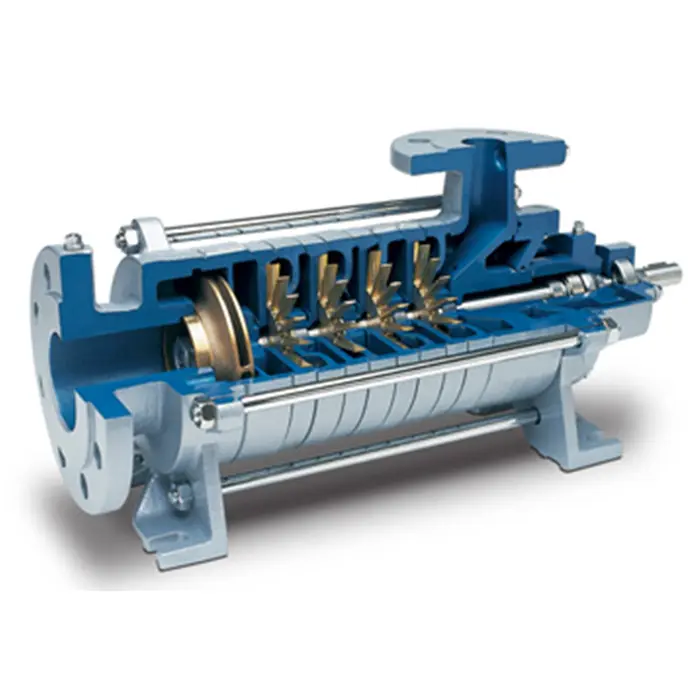

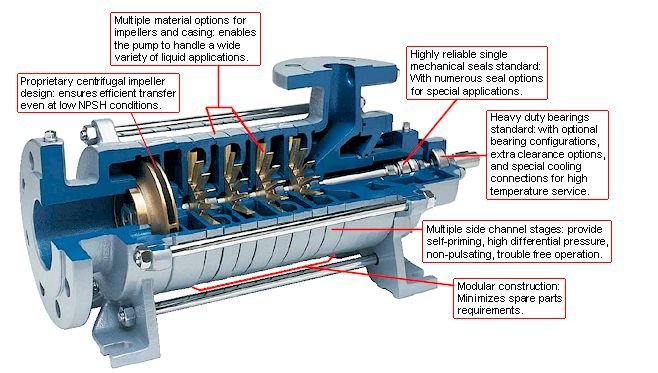

Corken SC Series Side Channel Pumps Multistage Regenerative Turbine Liquid Pump

Corken’ Model-SC Side Channel Pumps utilize a self-priming design making it ideal for applications with a low net positive suction head (NPSH). The multi-stage configuration also enables the Model-SC Side Channel pump to reach higher than normal differential pressures making it the ideal pump for applications such as propane carousel cylinder filling station, aerosol filling stations, vaporizer feed and selective catalytic reduction (SCR). The Model-SC is suitable for liquefied gases such as propane, ammonia, pentane, propylene, propylene oxide, refrigerants, vinyl toluene and liquids with low vaporous pressures like gasoline, glycol, methanol, mineral spirits, naphtha, water, soda ash & solvents.

- Available in six pump sizes

- Available with DIN & ANSI flanges (steel weld adapters available on the SC10 series only)

- Flow rate: Up to 185 gpm

- Working pressure: Up to 580 psi

- Differential pressure: Up to 250 psi

- Temperature range: -40 to 428 °F

- Viscosity: Up to 1,050 SSU

Corken’ Model-SC Side Channel Pumps utilize a self-priming design making it ideal for applications with a low net positive suction head (NPSH). The multi-stage configuration also enables the Model-SC Side Channel pump to reach higher than normal differential pressures making it the ideal pump for applications such as propane carousel cylinder filling station, aerosol filling stations, vaporizer feed and selective catalytic reduction (SCR). The Model-SC is suitable for liquefied gases such as propane, ammonia, pentane, propylene, propylene oxide, refrigerants, vinyl toluene and liquids with low vaporous pressures like gasoline, glycol, methanol, mineral spirits, naphtha, water, soda ash & solvents.

- Available in six pump sizes

- Available with DIN & ANSI flanges (steel weld adapters available on the SC10 series only)

- Flow rate: Up to 185 gpm

- Working pressure: Up to 580 psi

- Differential pressure: Up to 250 psi

- Temperature range: -40 to 428 °F

- Viscosity: Up to 1,050 SSU